...... up connected Carbide Burr Overview 1

8. THE SELECTION AND APPLICATION PRINCIPLES OF CARBIDE BURR.

① The selection of carbide burr shape

The different shapes of carbide burr have different application, in order to get the best processing effect of the workpiece, we should choose their shape correctly and reasonably. Here we have sorted out 13 shapes of carbide burr and their application for your reference:

|

Shape Code |

Shape Description |

Sketch Map |

Use Description |

|

Type A |

Cylinder Without End Cut |

|

Type A carbide burr is suitable for machining surface profile of workpiece. |

|

Type B |

Cylinder With End Cut |

|

Type B carbide burr is suitable for machining surface profile and the interchange of two right angle surface of workpiece. |

|

Type C |

Ball Nosed Cylinder |

|

Type C carbide burr is suitable for machining surface profile and circular arc profile of workpiece. |

|

Type D |

Ball Shape |

|

Type D carbide burr is suitable for machining circular arc profile, removing burrs of diameter and machining weld point before weld. |

|

Type E |

Oval Shape |

|

Type E carbide burr is suitable for machining circular arc profile of workpiece. |

|

Type F |

Ball Nosed Tree |

|

Type F carbide burr is suitable for machining circular arc profile of workpiece which in confined spaces. |

|

Type G |

Point Tree |

|

Type G carbide burr is suitable for machining circular arc profile which in confined spaces and acute-angled profile of workpiece. |

|

Type H |

Flame Shape |

|

Type H carbide burr is suitable for machining circular arc profile of workpiece. |

|

Type J |

60° Countersink |

|

Type J carbide burr is suitable for machining 60°counter boring and chamfering of workpiece. |

|

Type K |

90° Countersink |

|

Type K carbide burr is suitable for machining 90° counter boring and chamfering of workpiece. |

|

Type L |

Ball Nose Cone |

|

Type L carbide burr is suitable for machining narrow profile and surface profile of workpiece. |

|

Type M |

Cone Shape |

|

Type M carbide burr is suitable for machining narrow profile and surface profile of workpiece. |

|

Type N |

Inverted Cone |

|

Type N carbide burr is suitable for machining the chamfering of inside of workpiece. |

② The selection of carbide burr size

The size of carbide burr should be chose according to the size and machining allowance of the workpiece which need to be machined. When the finish size and allowance is big, we should choose the carbide burr with big size specifications, conversely, to choose small size specifications of the carbide burr.

③ The selection of carbide burr cut shape

► The cut space of carbide burr: the cut space can be divided into coarse space cut, fine space cut and standard space cut. The cut space of the carbide burr should be selected according to the allowance, the machining accuracy and the material properties of workpiece. The coarse space cut is suitable for machining workpiece with big allowance, low dimensional accuracy, big shape and position tolerance, big surface roughness and soft material. Conversely, to choose fine space cut. The standard space cut has good common performance. In use, we should decide cut space of carbide burr according to the machining allowance, dimensional accuracy and surface roughness requirements of the workpiece.

► The cut pattern of carbide burr: commonly, the cut pattern can be divided into single cut, double cut, diamond cut, aluminum cut, we choose the carbide burr cut pattern according to the material nature of the workpiece. In addition, the carbide burr with chip breaking groove are better than ordinary carbide burr in machining long cutting materials. Because after adding chip breaking groove, it can eliminate needle-like chips, chips become short and blunt, and easy to deal with, not easy to hurt. The chip breaking groove is distributed along one side of the spiral cut, so the finish of surface is higher than that of ordinary carbide burr.

► We have sorted out the common 8 kinds of cut shape of carbide burr with their application materials and the effect that can be achieved for your reference:

|

|

Fine single cut |

■ Suitable for fine processing of cast iron, steels with hardness less than 60 HRC, stainless steel and high temperature resistant materials such as nickel base alloy and cobalt base alloy. |

|

|

Standard single cut |

■ Suitable for processing of cast iron, steel with hardness less than 60HRC, stainless steel, nickel base alloy and titanium alloy. |

|

|

Coarse single cut |

■ Suitable for processing of light metal, non-ferrous metal. |

|

|

Fine double cut |

■ Suitable for processing of stainless steel, steels with hardness less than 60 HRC, stainless steel and high temperature resistant materials such as nickel base alloy and cobalt base alloy. |

|

|

Standard double cut |

■ Similar to a standard single cut, but with crossed cut. |

|

|

Coarse double cut |

■ High cutting performance for non-ferrous metals, brass, red copper, plastics and fiber reinforced plastics. |

|

|

Diamond cut |

■ It has good cutting performance for almost all materials whose hardness is less than 68HRC. |

|

|

Aluminum cut |

■ High cutting performance for aluminium and aluminium alloys, light metals, non-ferrous metals and plastics. |

9. THE SELECTION OF SHANK DIAMETER AND LENGTH OF CARBIDE BURR.

The main sizes of carbide burr are burr cutting head diameter D1 and shank diameter D2, the cutting head length L2 and total length L1 can be selected according to specific operation requirements.

① Standard type of carbide burr

Its 45mm length shank is the common specification for operation, the shank diameter D2 there are mainly 6mm, 8mm in metric size and 1/4 in inch size can be selected.

② Small size specification of carbide burr

The cutting head diameter of this kind of carbide burr is small, and the diameter of the shank is generally 3mm or 2.35mm in in metric size, and 1/8 in inch size for choice. In general, this kind of carbide burr made of solid carbide rod, because of its high concentricity and accuracy, it is more suitable for finishing precision parts.

③ Extended shank of carbide burr

The length of the steel shank can be lengthened according to the special working conditions, generally used the length of 75mm, 100mm, 150mm, 300mm. Especially suitable for processing the place which difficult to contact or deep areas. But it is not the longer the the better, because too long of shank will cause certain vibration during grinding operation, the longer of shank, the bigger of vibration.

When choosing the size of carbide burr, you can choose the right sizes according to the requirements of the operation. When using, you must wear protective glasses.

10. GUIDE FOR BRAND SELECTION OF CARBIDE BURR.

Here the carbide burr brand is divided into Chinese brand and foreign brand, in terms of quality, some Chinese brands are indistinguishable from foreign brands in common types, even some Chinese brands have better quality than foreign second-tier brands. But compared with foreign top brands such as the PFERD from German, there is still a gap, especially in the areas of unconventional shapes and cut shapes, although the gap is closing, it's going to take some time. In terms of price, Chinese brands have a relatively big advantage.

In the high-end manufacturing field used carbide burr, you can choose foreign top brands, because of their better high precision. In the general manufacturing field with carbide burr in quantity, as far as possible to choose the trusted Chinese brands with best cost performance, this can save you a lot of money. You can contact and learn more about Doma carbide burr.

11. SELECTION OF COATING FOR CARBIDE BURR.

The commonly used carbide burr coating is TIN (golden yellow) and ALTIN (gray black).

① Improved anti-stick properties

② High efficiency debris discharge

③ decrease of load

④ Extend tool life

12. HOW TO IDENTIFY THE QUALITY OF CARBIDE BURR?

There are many kinds of carbide burr in the market, with different prices and brands. So how to distinguish their quality is very important. We can make a preliminary identification from the following aspects, but the most reliable identification is the real use test.

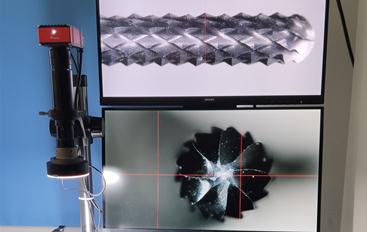

① Brazing way. At present, there are two brazing way of carbide burr in the market, flat bottom silver brazing and copper brazing with hole bottom. The flat bottom silver brazing has a simpler welding structure with less welding stress, low welding temperature, it can keep the properties of the tungsten carbide and steel shank from being greatly affected in welding process. So in general, flat bottom silver brazing there is better welding stability and quality, of course, its cost is higher.

② The Concentricity. The concentricity of good carbide burr is generally controlled within 0.1mm

③ The depth and thickness of the cuts. The cut appearance of good carbide gives a thick and reliable feel, and there is a clear cut feeling when touching the cut.

④ The brightness of cut. The brightness of the cut is a lateral confirmation of the sharpness of the cut. The brighter the cut, the sharper the cut, otherwise it is the opposite.

⑤ The performance of tungsten carbide is also a key factor, but this item needs special equipment to test, we need to inspect the hardness, bending strength, porosity and metallographic structure of the tungsten carbide.

13. HOW TO USE CARBIDE BURR?

The carbide burr is clamped on the high-speed rotary tool for manual control, so when using, we need to clamp the carbide burr and fixed correctly. In order to obtain the best stability, when you install the carbide burr, the shank of carbide burr must be fully inserted with a minimum exposed length, and the cutting direction should be from right to left evenly, can't back and forth, at the same time, please do not force too hard, we should use the entire surface of the cut as much as possible to work.

Because the pressure and feed speed of the carbide burr work depends on the working conditions and the experience and skills of the operator.Although experienced operators can keep pressure and feed speed within reasonable limits, we want to make some points here: first of all, avoid too much pressure when the speed of the grinder becomes slow, otherwise it will make the carbide burr overheated and easy to get blunt; Secondly, as far as possible to make the burr head maximum get to the workpiece, because this allows more cut to penetrate the workpiece, the processing effect can be better; Finally, please avoid the burr shank get to the workpiece when it work, otherwise it will cause the carbide burr to overheat, then damage or even destroy brazed burr head.

We should avoid making any unnecessary trimming of the burr cut, to prevent damage to cut shape and coating peeling, thereby keep the service life of carbide burr. Replace or re-sharpen the blunt carbide burr in time to prevent it from being completely damaged. Blunt carbide burr are slow to cut, it has to increase the pressure of the grinding machine to increase the cut speed, this will certainly cause damage to the carbide burr and grinders, this cost is far more than the cost of replacing or resharpening the blunt carbide burr.

Lubricants can be used in conjunction with the operation. Liquid wax lubricant and synthetic lubricant are more effective. Lubricants can be added regularly to the burr head.

Higher working speed is very important for the efficient and economical use of rotary files.The higher operating speed is also helpful in reducing chip buildup in the grooves.It is also helpful for cutting the corners of the workpiece and reducing the possibility of cutting runout or wedge deviation. However, this will also increase the possibility of cracking of the carbide burr steel shank.

The meaning of a carbide burr for a product is what people often say: "Details determine success or failure."

Please wear a protective eye mask when working to prevent the damage of cutting debris flying.

14. THE MATTERS NEED ATTENTION WHEN YOU USE CARBIDE BURR.

① Choose the matching electric grinder or pneumatic tool with stable performance, it's best to choose a trusted brand.

② Before the operation, first, you need to choose the appropriate speed range according to the usage speed (please refer to the recommended starting speed condition). Low speed will affect the life of carbide burr and surface finish of workpiece, meanwhile low speed will affect the chip removal, it will generate mechanical flutter, then lead to premature wear of the carbide burr.

③ Before use, please confirm that the workpiece is fixed or not and the chuck of electric grinder is correct and tight or not.

④ To prevent cutting chips splash damage, you must wear a suitable safety goggles when working.

⑤ Keeping it idling before use to make sure the concentricity of the carbide burr is good, eccentricity and vibration can cause premature wear of carbide burr and damage the workpiece.

⑥ Do not use too much pressure, too much pressure will reduce the life of carbide burr and its use efficiency.

⑦ Do not run a carbide burr in the conditions with full of combustible gas.

⑧ Do not let carbide burr stuck in grooves and crevices when use.

15. HOW TO KEEP CARBIDE BURR PROPERLY?

When keeping the carbide burr for a short time, to avoid long-term exposure to the air, it should be put back into the original package. If you need to keep the carbide burr for a long time, before you put it back in the original package, you need to coat them with anti-rust oil to avoid the steel shank rust and the surface of tungsten carbide oxidation.

16. HOW TO DEAL WITH DISCARDED CARBIDE BURRS?

Please do not throw away the carbide burr that have become blunt to the trash can, you can aggregate them all together, then contact the local carbide products scrap recyclers, not only you will get a extra pay, but you will also be doing your bit to protect the environment.

17. WHERE TO BUY CARBIDE BURR?

If you're an individual or a small business buyer, you can buy the carbide burrs from Amazon or your local hardware store. If you are a wholesaler or an end user enterprise purchasing in large quantities, you can directly contact the carbide burr manufacturer to place an order. Please be sure to look for a reliable carbide burr manufacturer, it is better to do a test before bulk purchase.

The Precision Measurement and Detection of Tools

The Precision Measurement and Detection of Tools

Carbide Burr Overview 1

Carbide Burr Overview 1

The Test of Tire Drill Bit

The Test of Tire Drill Bit

The Carbide Burr Brazing Technology

The Carbide Burr Brazing Technology