1. WHAT IS THE CARBIDE BURR?

Carbide burr, also known as burr bit, burr cutter, carbide burr bit, carbide die grinder bit etc. Strictly speaking, the carbide burr is a kind of rotary cutting tool which is clamped on pneumatic tools or power tools and specially used to remove metal burr, welding scar, weld cleaning. It is mainly used in the rough machining process of the workpiece with high efficiency.

2. THE COMPONENT OF CARBIDE BURR?

Carbide burr can be divided into brazed type and solid type. The brazed type is made of carbide head part and steel shank part brazed together, when the diameter of burr head and shank are not same, the brazed type is used. The solid type is made of solid carbide when the diameter of burr head and shank are same.

3. WHAT IS CARBIDE BURR USED FOR?

Carbide burr have been widely used, it is an important way to improve production efficiency and achieve the mechanization of fitter. In recent years, with the increasing number of users, it has become a necessary tool for fitter and repairman.

The main uses:

♦ chip removing.

♦ shape modification.

♦ edge and chamfer finish.

♦ perform preparatory milling for build up welding.

♦ weld cleaning.

♦ clean casting materials.

♦ improve the geometry of the workpiece.

The main industries:

♦ Mold industry. For finishing all kinds of metal mold cavity, such as shoe mold and so on.

♦ Engraving industry. For engraving all kinds of metal and non-metal, such as craft gift.

♦ Equipment manufacturing industry. For cleaning the fin, burr, welding-seam of casting, forge piece and weldment, such as casting machine factory, shipyard, wheel hub polishing in automotive factory, etc.

♦ Machinery industry. For processing the chamfer, round, groove and keyway of all kinds of mechanical parts, cleaning pipes, finishing the surface of the inner hole of the machine parts, such as machinery factory, repair shop and so on.

♦ Engine industry. For sleeking the flow pass of impeller, such as car engine factory.

♦ Welding industry. For sleeking the welding surface, such as riveting welding.

4. THE ADVANTAGES OF CARBIDE BURR.

♦ All kinds of metals (including hquenched steel) and non-metallic materials (such as marble, jade, bone, plastic) with hardness below HRC70 can be cut arbitrarily by carbide burr.

♦ It can replace small grinding wheel with shank in most work, and no dust pollution.

♦ High production efficiency, tens of times higher than the processing efficiency of manual file, and more than ten times higher than the processing efficiency of small grinding wheel with shank.

♦ With good processing quality, high surface finish, carbide burr can process various shapes of mold cavity with high precision.

♦ Carbide burr there is a long service life, 10 times more durable than high speed steel cutter, and 200 times durable more than aluminum oxide grinding wheel.

♦ Carbide burr is easy to use, safe and reliable, it can reduce labor intensity and improve the working environment.

♦ The economic benefit after use carbide burr is greatly improved, and the comprehensive processing cost can be reduced tens of times by use carbide burr.

5. THE RANGE OF MACHINED MATERIALS OF CARBIDE BURR.

| Application | Materials | ||

| Used for deburring, milling of preparation process, surfacing welding, welding spot machining, forming machining, casting chamfering, sinking machining, cleaning. | Steel, Cast Steel | Not hard steel, not heat treated steel, strength not exceeding 1.200N/mm²(<38HRC) | steel structure, carbon steel, tool steel, non - alloy steel, carburizing steel, cast steel |

| Hard steel, heat treated steel, strength over 1.200N/mm²(>38HRC) | tool steel, tempered steel, alloy steel, cast steel | ||

| Stainless Steel | Rust proof and acid proof steel | austenitic and ferritic stainless steels | |

| Nonferrous Metals | soft nonferrous metals | aluminum | |

| brass, red copper, zinc | |||

| hard nonferrous metal | aluminum alloy, brass, copper, zinc | ||

| brass, titanium/titanium alloy, duralumin alloy (high silicon content) | |||

| heat-resisting material | Nickel base and cobalt base alloys (engine and turbine manufacturing) | ||

| Cast Iiron | grey cast iron, white cast iron | nodular graphite / ductile iron EN-GJS(GGG) | |

| white annealed cast iron EN-GJMW(GTW), | |||

| black iron EN-GJMB(GTS) | |||

| Used for milling, forming processing | Plastic, Other Materials | fiber reinforced plastics (GRP/CRP), fiber content ≤40% | |

| fiber reinforced plastics (GRP/CRP), fiber content >40% | |||

| Used for trimming,form milling of cutting hole | thermoplastic | ||

|

The recommended speed list for carbide burr use. |

||||||

|

The speed range is recommended for different materials and burr diameters |

Burr Diameters |

|||||

|

3mm (1/8") |

6mm (1/4") |

10mm (3/8") |

12mm (1/2") |

16mm (5/8") |

||

|

Maximum Operating Speed (rpm) |

90000 |

65000 |

55000 |

35000 |

25000 |

|

|

Aluminum, Plastic |

Speed range |

60000-80000 |

15000-60000 |

10000-50000 |

7000-30000 |

6000-20000 |

|

Recommended starting speed |

65000 |

40000 |

25000 |

20000 |

15000 |

|

|

Copper, Cast Iron |

Speed range |

45000-80000 |

22500-60000 |

15000-40000 |

11000-30000 |

9000-20000 |

|

Recommended starting speed |

65000 |

45000 |

30000 |

25000 |

20000 |

|

|

Mild Steel |

Speed range |

60000-80000 |

45000-60000 |

30000-40000 |

22500-30000 |

18000-20000 |

|

Recommended starting speed |

80000 |

50000 |

30000 |

25000 |

20000 |

|

|

Heat treated steel, Stainless steel |

Speed range |

60000-80000 |

30000-45000 |

19000-30000 |

15000-22500 |

12000-18000 |

|

Alloy steel, Titanium |

Recommended starting speed |

80000 |

40000 |

25000 |

20000 |

15000 |

* The above operation is based on the shank length of 45mm (the maximum exposed length of shank after clamping is 10mm).

* The recommended speed of extended shank is 15000rpm.

...... down connect Carbide Burr Overview 2

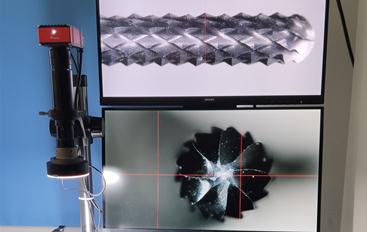

The Precision Measurement and Detection of Tools

The Precision Measurement and Detection of Tools

Carbide Burr Overview 2

Carbide Burr Overview 2

The Test of Tire Drill Bit

The Test of Tire Drill Bit

The Carbide Burr Brazing Technology

The Carbide Burr Brazing Technology