The brazing technology and brazing material selection directly determine the quality level of carbide burr.

The majority of domestic manufacturers, even some manufacturers in other countries, they use copper brazing with a hole of carbide blanks. Although the carbide burr made in this way is more cheap, because it saves on tungsten carbide raw materials and welding material is the cheapest, but the carbide burr produced in this way is of poor quality and very unstable, because there are two key issues involved, one is welding temperature and another is welding stress control.

Chengdu Doma Carbide Tools Co., Ltd. was originally a research and development enterprise of cemented carbide materials. We have a better understanding of the properties of cemented carbide materials than other tool manufacturers who need to purchase cemented carbide blank from outside.

Firstly, Doma carbide burr use Sandwich type silver welding material, the temperature required for Sandwich type silver welding material is around 800°C, the temperature required for copper brazing material is around 1100°C. According to relevant research reports and our experience, when the temperature exceeds about 900°C, the surface of cemented carbide begins to oxidize rapidly, the cobalt in carbide burrs tends to liquefy, and the metallographic structure of cemented carbide begins to change. So, in the process of copper brazing, the properties of carbide burr there will be a degree of damaged, but in the process of Sandwich type silver welding, the damage to the properties of carbide burr is very limited, it's almost negligible.

Then, the design of Sandwich type silver welding sheet, its two ends of the welding sheet are silver and the interlayer is copper alloy, this kind of welding material can significantly reduce the welding stress, it do not cause micro cracks in the carbide burrs, at the same time, its welding strength is much higher.

Finally, Doma use the automatic welding machine is also a very important factor, in the automatic welding process, the carbide cutting head and steel shank are automatic butt-jointed, no human involvement, so its stability and uniformity is much better than human manual welding.

The Precision Measurement and Detection of Tools

The Precision Measurement and Detection of Tools

Carbide Burr Overview 2

Carbide Burr Overview 2

Carbide Burr Overview 1

Carbide Burr Overview 1

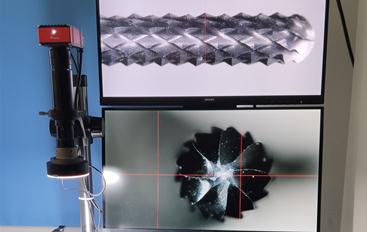

The Test of Tire Drill Bit

The Test of Tire Drill Bit